Read about recent innovations and developments in building and construction.

As our nation and the global community grapple with climate change, mounting attention is focusing on the impact of the built community. The building sector’s outsized contribution to greenhouse gas emissions is estimated to be a whopping 40%.

Created by Oracle in collaboration with curators, ‘Future of Energy,’ aims to help visitors better understand how they use energy, ways to conserve it, and their role in building a clean energy future. On view through July 6, 2022, “FUTURES” is the Smithsonian’s first major building-wide exploration of the future.

Climate and resource protection are some of the most pressing issues for our future world. There is a common misconception that building materials—such as polycarbonate translucent panels—cannot be sustainable.

The quality of education and student wellness is linked to the design of the built environment. Floors play a significant role in supporting healthy educational environments.

For decades, organizations like the U.S. Green Building Council (USGBC), the Green Building Initiative (GBI), and the American Society of Interior Designers (ASID) have been leaders in educating architects, builders, designers and other stakeholders on the importance of improving the health, environmental and sustainability impacts of buildings and materials. That is why the American Chemistry […]

A new life cycle analysis comparing spray foam with other conventional types of non air sealing insulation evaluates spray polyurethane foam’s (SPF’s) lifespan pollution footprint using carefully modeled virtual homes. When the right blowing agents are used in SPF production, the estimated savings in energy use rapidly compensates for the production phase.

The site will manufacture ArmorBuilt™ fire-resistant wrap for wooden utility poles. Hexion Inc. intends to expand its Portland, Oregon, manufacturing site to support its recently-launched ArmorBuilt fire-resistant wrap, which, the company states, can greatly improve fire protection when applied to wood utility poles and help protect vital community infrastructure.

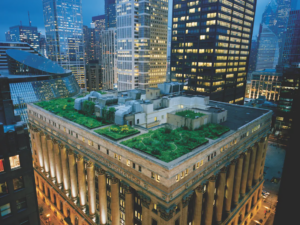

With green roof projects on the rise, it can be hard to know where to begin to design a high-performing green roof. More and more manufacturers are developing green roof materials that range from plant trays to waterproofing systems and we have compiled a list of green roof materials to consider.

ACEEE’s 2020 research found that low-income, Black, Hispanic, and Native American households all face dramatically higher energy burdens – spending a greater portion of their income on energy bills – than the average household.

Read more at American Council for an Energy-Efficient Economy »

Dow and the U.S. Green Building Council (USGBC) shared the results of their inaugural Carbon Challenge, which received a total of 63 entries across 16 cities in Northern Asia. Jointly, these 63 buildings saved 38,000 metric tons of carbon dioxide equivalent year over year (equivalent to over 600,000 tree seedlings grown for 10 years), and reduced greenhouse gas (GHG) emissions on average more than 2% year over year.